The world's first demonstration of the high-efficiency hydrogen liquefaction by magnetic refrigeration

In hydrogen liquefaction by the magnetic refrigeration, the adiabatic

demagnetization method to generate temperatures below 1 K is extended to

the high-temperature region.

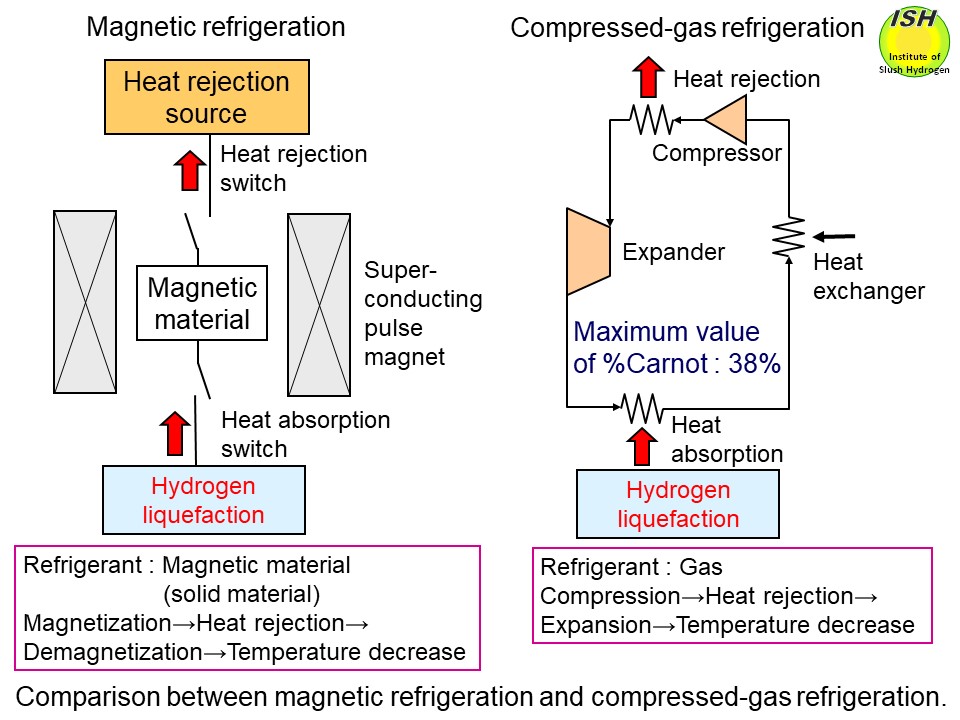

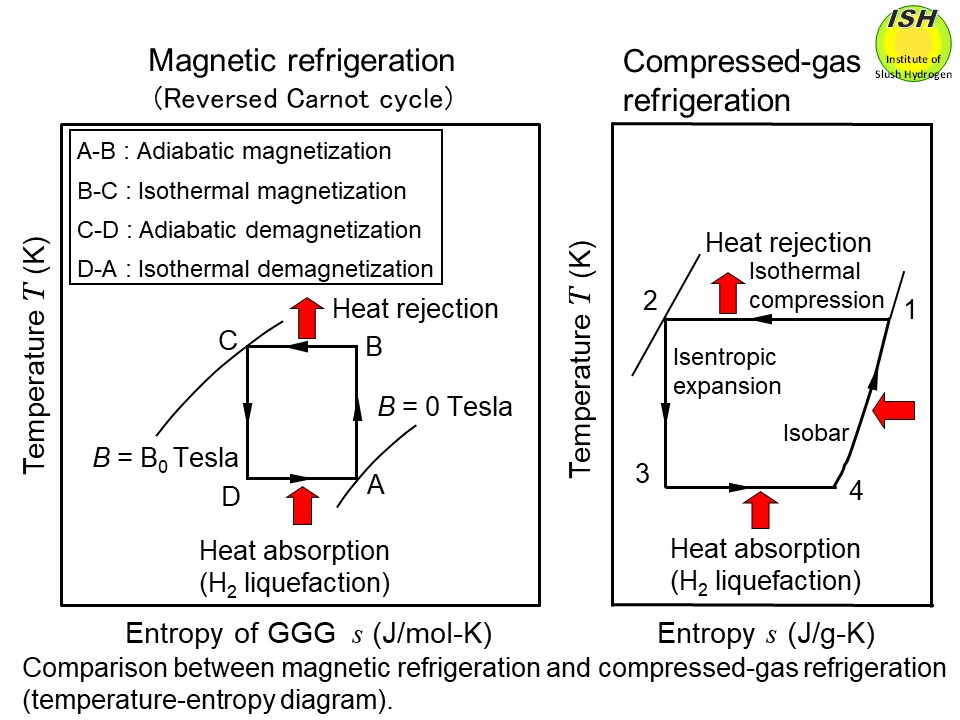

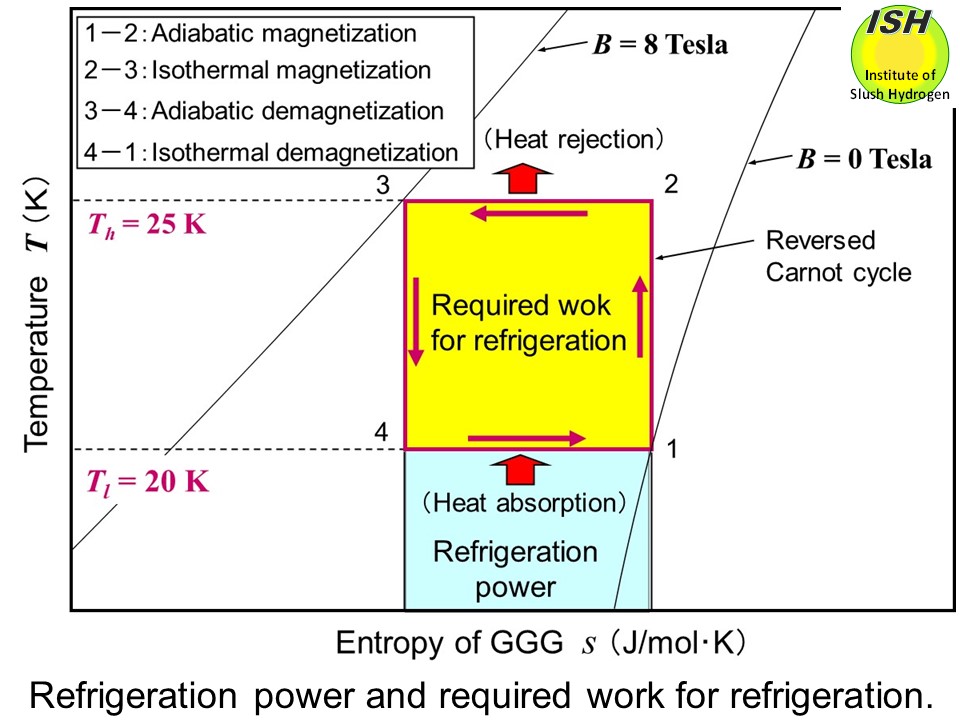

The principles of magnetic refrigeration and compressed-gas refrigeration

are illustrated in the above figure. The temperature-entropy diagrams of magnetic material and gas as a refrigerant

in liquefaction cycle are respectively shown in the above figure. The magnetic refrigeration for hydrogen liquefaction uses an external

magnetic field to magnetize and demagnetize a magnetic material in repeated

cycles, thus producing low temperatures through the magnetocaloric effect.

Since the magnetic refrigeration method can ideally realize the reversed

Carnot cycle, it is possible to achieve theoretically a higher %Carnot

efficiency* in contrast to the compressed-gas refrigeration method as noted

in the above figure [4].

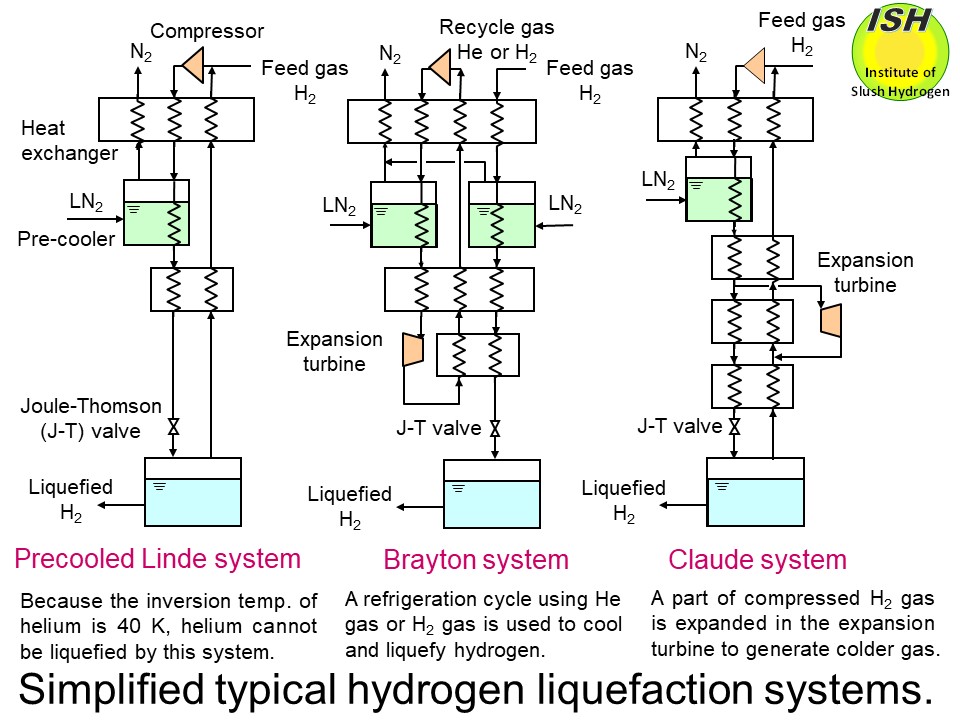

Most of the practical hydrogen liquefiers using the compressed-gas method

utilize a precooled Linde system, a Brayton system, or a Claude system

as illustrated in the figure below [9, 10]. The maximum efficiency is expected to be about 50% in terms of

the %Carnot efficiency*, compared to about 38% of the %Carnot efficiency

for the world’s largest hydrogen liquefier (liquefaction capacity: 60 ton/day)

using the compressed-gas method. Also, given the use of solid magnetic

material, which has much greater entropy density than gas, the liquefier

can be made compact.

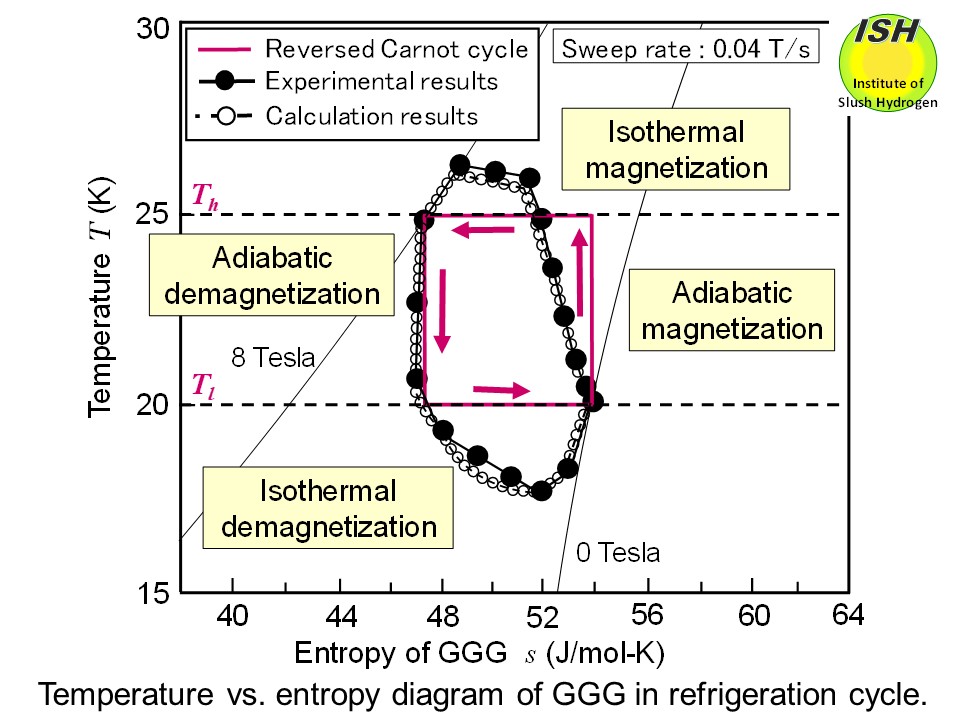

Firstly, before the hydrogen liquefaction experiment, the magnetic refrigeration

test was conducted to establish the working procedure of the reversed Carnot

cycle and the measurement method of refrigeration power at temperature

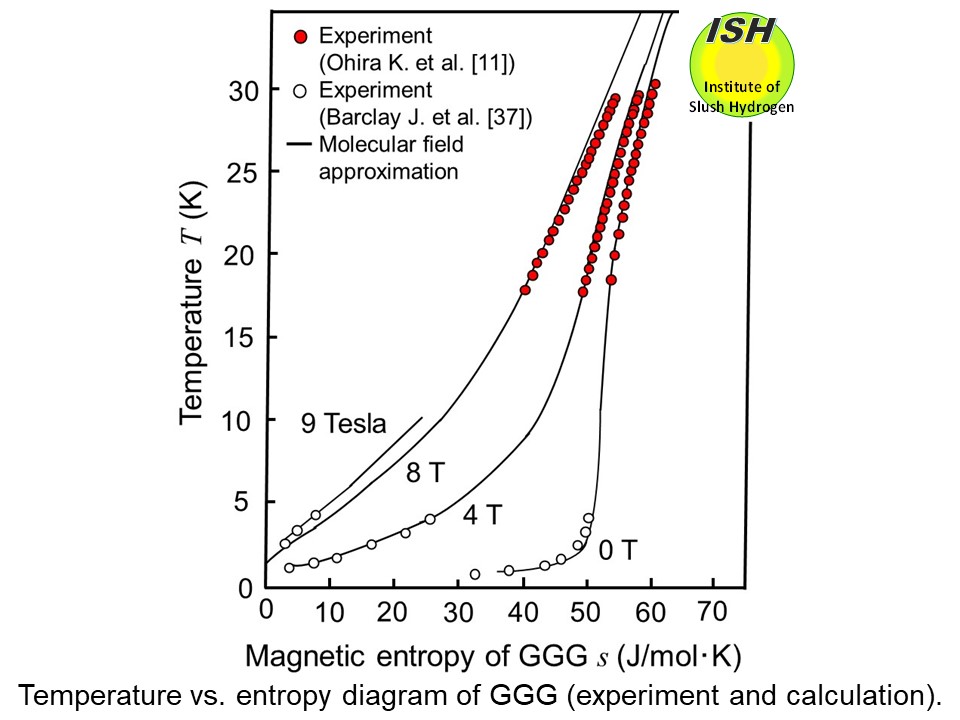

of 20 K. Gadolinium gallium garnet (GGG: Gd3Ga5O12) was selected as a magnetic material. However, since only few reliable

experimental data were available on the thermo-physical properties of GGG

around the liquid hydrogen temperature, we measured the entropy of GGG

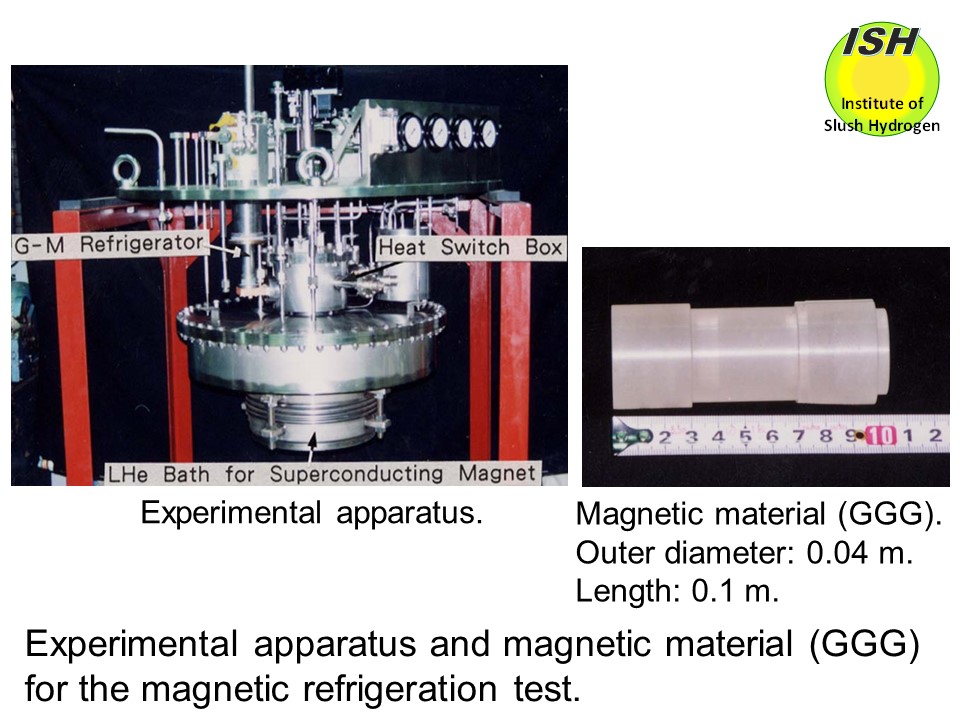

in the range of 18 to 30 K and 0 to 8 Tesla as shown in the figure below. The magnetic refrigerator mainly consists of a superconducting magnet

(the maximum magnetic field of 8 Tesla and the magnetization/demagnetization

sweep rate of 0.04 Tesla/s), a Gifford-McMahon type refrigerator (UCR31W

made by MHI) as a heat rejection source (Th = 25 K), and an electrical heater wound around GGG, operating below 20

K as a heat absorption switch, which is also used for the measurement of

refrigeration power (Tl = 20 K) in the figure below [11]. The experimental apparatus and magnetic material (GGG) are shown

in the photo below. The magnetic refrigeration cycle was operated in the range of 20 to 25

K and 0 to 8 Tesla, and the magnetization/demagnetization sweep rate of

0.04 Tesla/s. The temperature-entropy diagram of the magnetic material

during the experimental magnetic refrigeration process and the reversed

Carnot cycle are illustrated in the figure below. The numerical result of cycle simulation using heat-transfer performances

of the absorption and rejection heat switches, etc. as input data is also

shown in the figure, which agrees very well with the experimental result.

The refrigeration powers of 0.21 W and 0.22 W at 20 K were obtained in

the experiment and numerical result, respectively [11]. The reasons the

ideal reversed Carnot cycle indicated as a rectangle cannot be achieved

and the refrigeration power is small are the insufficient heat-transfer

performance of heat absorption and heat rejection switches and the low

sweep rate of magnetization/demagnetization.

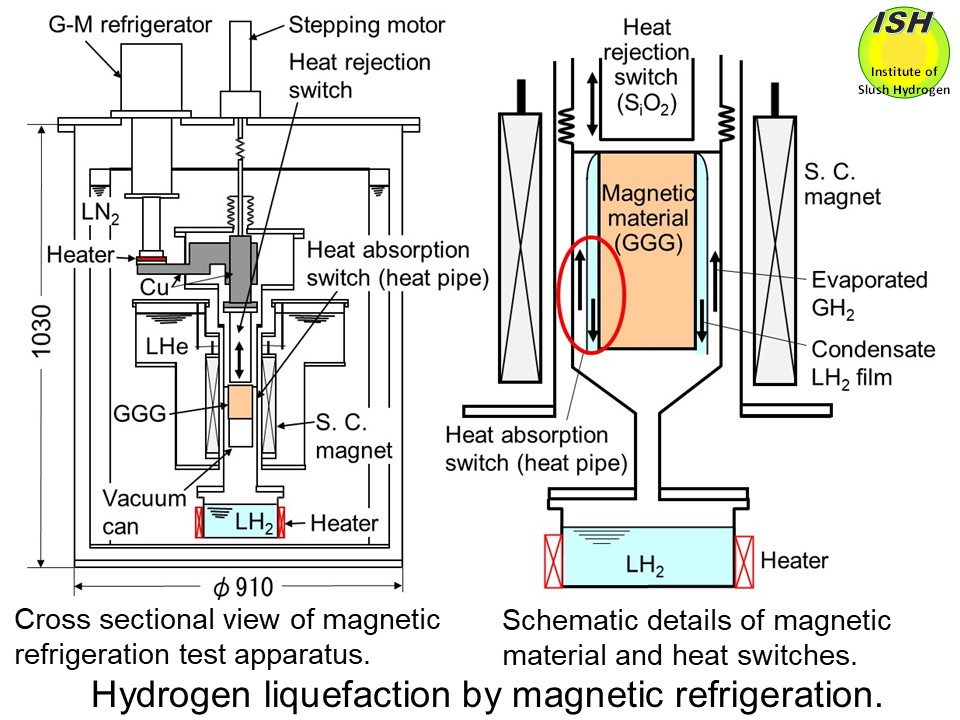

Secondly, the hydrogen liquefaction experiment was conducted after improvements

in the heat-transfer performance of heat absorption and heat rejection

switches. The hydrogen gas (temperature of 20.3 K) evaporated in a liquid

hydrogen vessel heated by an electrical heater was liquefied by the magnetic

refrigeration method. Cross sectional view of the test apparatus, and details

of magnetic material and heat switches are shown in the figure below. Gadolinium gallium garnet (GGG) was selected as a magnetic material.

The magnetic refrigerator mainly consists of a superconducting pulse magnet

(the maximum magnetic field of 5 Tesla and the maximum magnetization/demagnetization

sweep rate of 0.36 Tesla/s), a Gifford-McMahon type refrigerator (UCR31W

made by MHI) as a heat rejection source (Th = 25 K), and a heat pipe as a heat absorption switch for hydrogen condensation/liquefaction

(Tl = 20.3 K) [12]. In the thermal design of the high-performance heat pipe,

the Nusselt eq. was applied to evaluate the condensing heat-transfer coefficient

of hydrogen as described in the page "Hydrogen condensation and liquefaction".

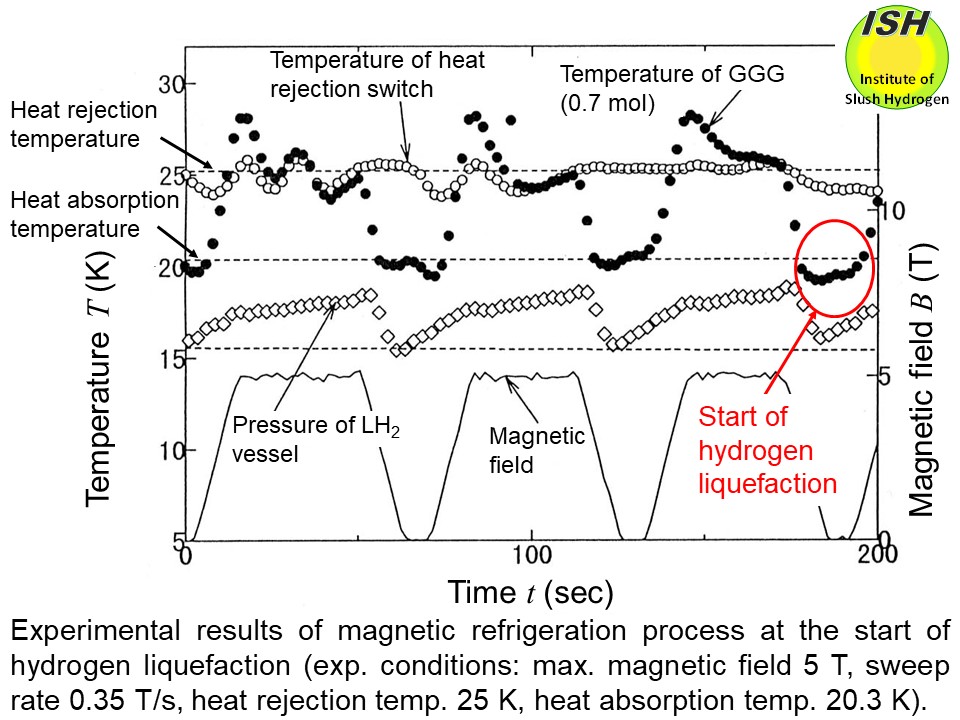

The magnetic refrigeration cycle for hydrogen liquefaction operated in

the range of 20.3 to 25 K and 0 to 5 Tesla. When the magnetic refrigeration

cycle is started, the GGG temperature drops below the temperature of hydrogen

liquefaction (20.3 K) after several cycles. The figure below shows changes with time of the GGG temperature, the temperature of heat

rejection switch, the pressure of the liquid hydrogen vessel continuously

heated by a heater, and the magnetic field in the refrigeration process.

At the last cycle in the figure, the refrigeration process becomes a steady-state

condition and the GGG temperature decreases sufficiently below the temperature

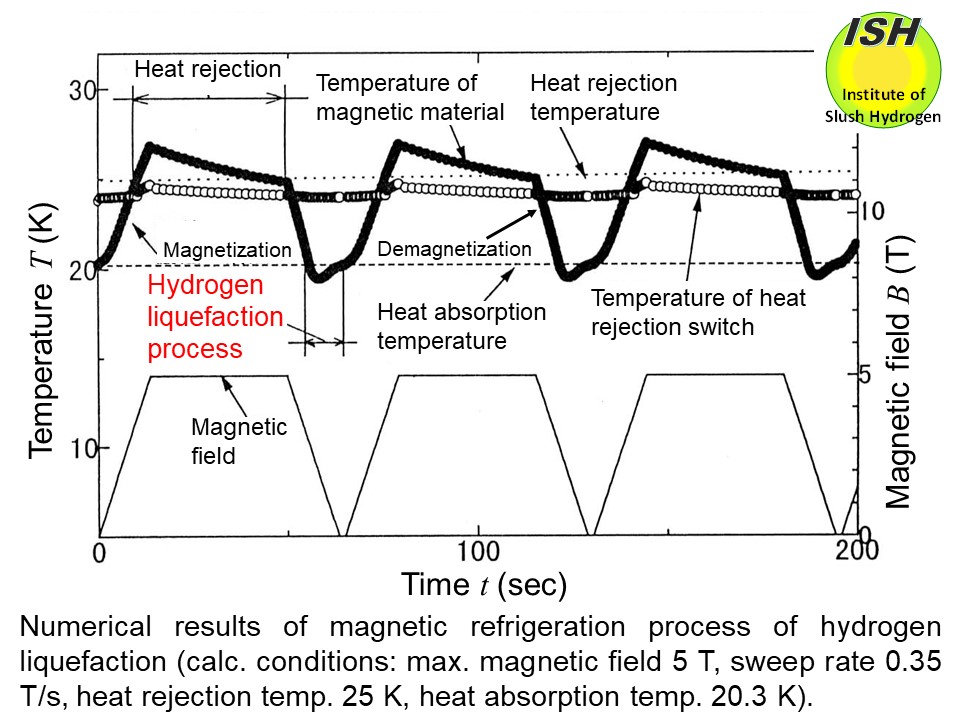

of 20.3 K. The hydrogen liquefaction cycle was numerically analysed using

heat-transfer performances of the absorption and rejection heat switches,

etc. as input data. The numerical result of cycle simulation is shown in

the figure below, which approximately agrees well with the experimental result.

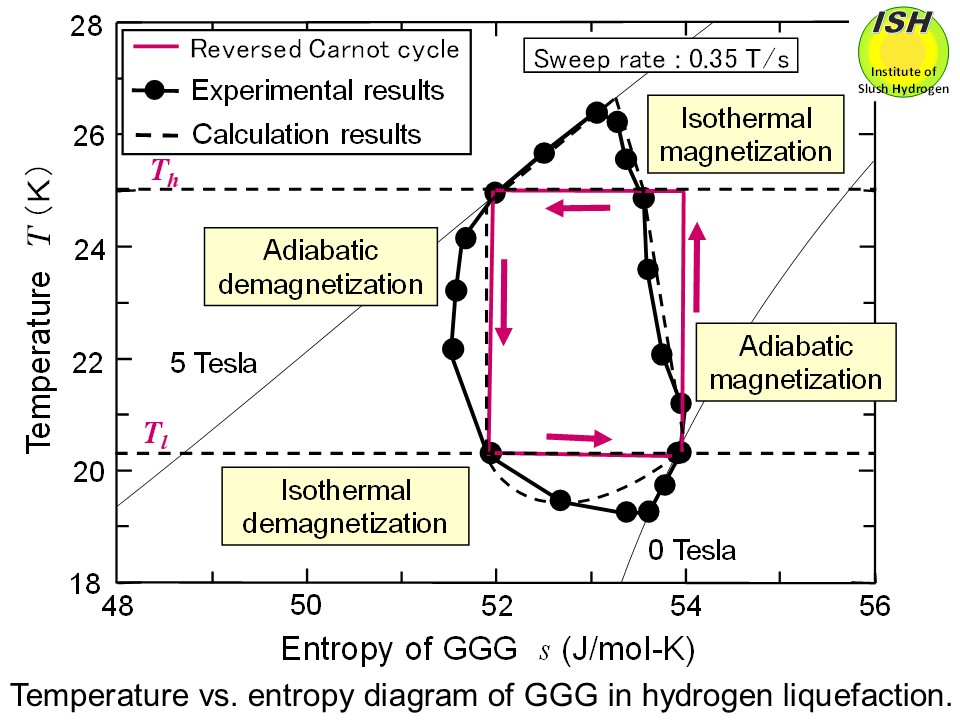

The temperature-entropy diagram of the magnetic material during the steady-state

hydrogen liquefaction process and the reversed Carnot cycle are illustrated

in the figure below, which operates at the maximum field of 5 Tesla and a magnetization/demagnetization

sweep rate of 0.35 Tesla/s. The reasons the ideal reversed Carnot cycle

indicated as a rectangle cannot be achieved are the insufficient heat-transfer

performance of the heat absorption and heat rejection switches, and the

influence of uncondensed hydrogen gas (continuously evaporating from the

vessel) around the magnetic material.

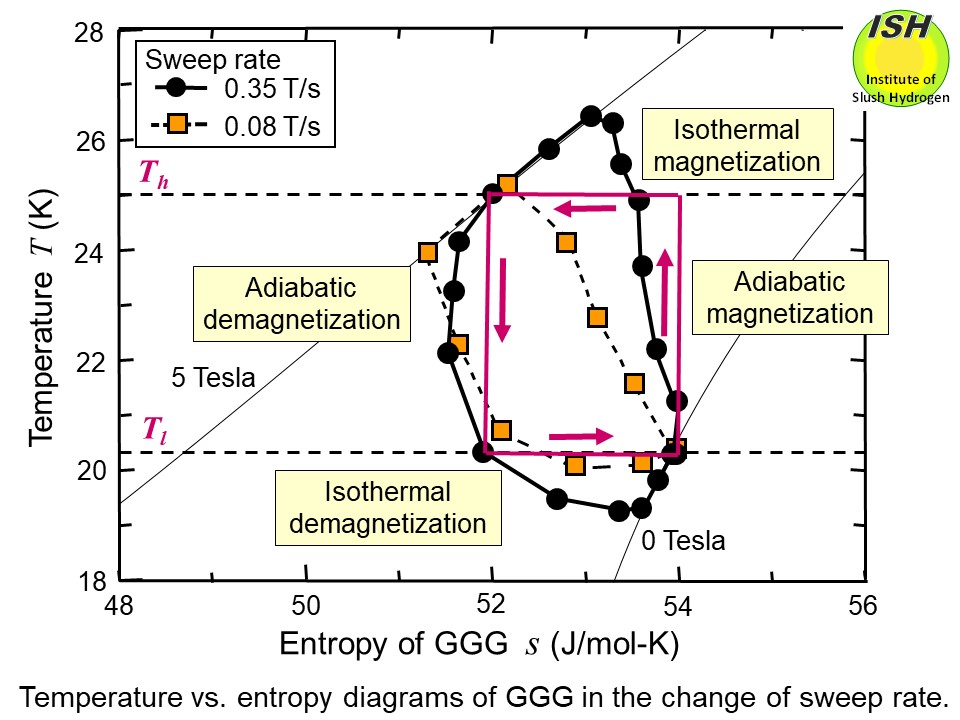

The effect of the sweep rate on the magnetic refrigeration cycle is shown

in the figure below, and magnetization/demagnetization sweep rates are 0.08 and 0.35 Tesla/s.

When the sweep rate is slow, the distortion of the cycle would be enhanced,

decreasing the heat rejection temperature and also the change of entropy

in the isothermal heat absorption process, resulting in a decreased refrigeration

power.

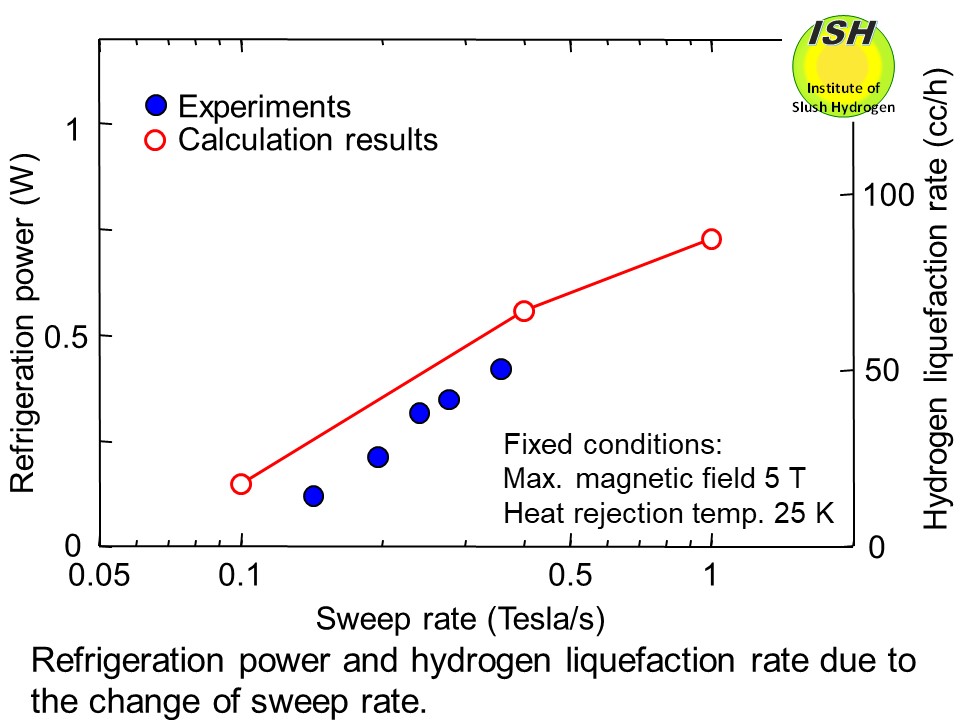

In the hydrogen liquefaction experiment, at the fastest magnetization/demagnetization

sweep rate of 0.36 T/s, as shown in the figure below, the maximum refrigeration power of 0.4 W at 20.3 K (liquefaction rate:

3.55 g/h or 50 cc/h) with the %Carnot efficiency* of 37% and the liquefaction

efficiency** of 78% was obtained.

The achievement of 37% for the %Carnot efficiency in a small-scale liquefaction

experiment (3.55 g/h or 50 cc/h) demonstrates the high efficiency of this

method.

The world’s first high-efficiency hydrogen liquefaction using magnetic

refrigeration is also demonstrated [11, 12].

For hydrogen liquefaction, a multistage magnetic refrigerator from room

temperature to liquid hydrogen temperature has been proposed, and research

and development work is in progress. A method has also been proposed for producing slush hydrogen from liquid

hydrogen, using magnetic refrigeration to produce temperature below 14

K.

* %Carnot efficiency: The ratio of the reversed Carnot work to the actual

work per unit mass liquefied. %Carnot efficiency = FOM (Figure of Merit)×100

(%).

** Liquefaction efficiency: The ratio of the rerigeration power of the

experiment to that of the reversed Carnot cycle at the refrigeration (or

liquefaction) temperature.